Friends, today in this article we will learn about distribution transformers, I am going to give information about all these in a very good way. So let’s start.

Distribution Transformer

Distribution –

This type of distribution transformers are installed at substations. In distribution, 11000 volts and 66000 volts are stepped down to 440 volts and delivered to the consumer. These are small in size from 5 kVA to 500 kVA and large in size from 500 kVA to 2000 kVA.

Transmission –

Step-up transformers are used for transmission. 6.6 kV is passed through the transmission line by increasing the voltage to 33kV or 132kV.

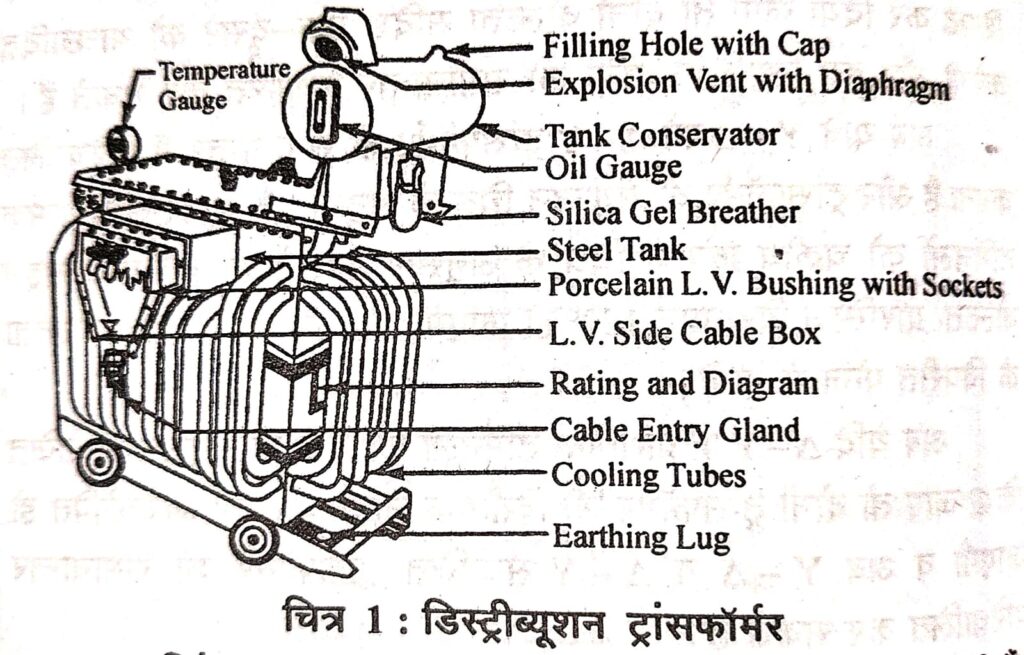

The main parts of a distribution transformer are as follows-

- Filling hole with cap

- Temperature gauge

- Explosion vent

- Conservator

- Oil gauge

- Breather with silica gel

- Steel tank

- Porcelain bushing with socket

- LV side cable box

- Name plate

- Cooling tube

- Wheel

- Earth point or earthing plug

- Primary and secondary winding

The above parts are shown in Figure 2.

Winding –

There are two windings, primary and secondary. Supply is given from the primary and supply is taken from the secondary.

If the primary winding of the transformer receives more voltage than the secondary winding, then it is called high tension (HT) winding and if the secondary winding receives less voltage than the primary winding, then it is called low tension (LT) winding.

Main Steel Tank –

This tank is made of soft iron sheets. Three phase winding is kept in it and transformer oil is filled in it. Cooling tubes are fitted on both sides of this tank. Wheels are fitted for carrying it here and there and conservator and breather insulators are fitted on top.

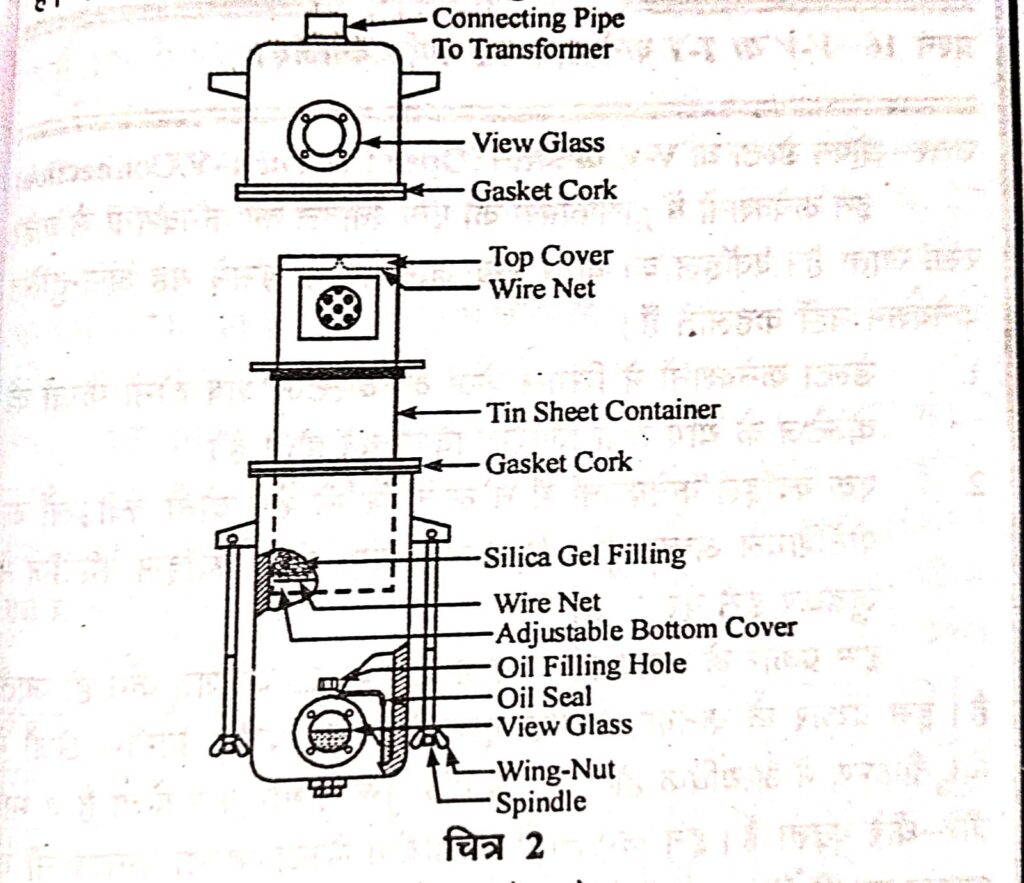

Conservator Tank –

This conservator tank is drum shaped. It is connected with the main tank at the top. It is half filled with oil and is in contact with the oil of the main tank through a pipe. Hot oil from the main tank comes into the conservator tank and the oil cools down on coming in contact with air in the conservator. This moisture-free cold air comes from the breather.

Breather –

It is box shaped. A substance called silica gel is filled in it. Air comes in it from outside. Moisture-free air is allowed to enter the conservator. It is connected to the conservator by pipes. Transformer oil deteriorates due to moisture.

Moisture may occur due to three reasons. Corrosion of gaskets, absorption from air in contact with the oil surface, or deterioration of insulation at high temperature. The effect of moisture in oil reduces the dielectric strength. The following methods are used to eliminate the effect of moisture:

- By using silica gel breather

- By using rubber diaphragm

- By using gas cushion

- By using thermo siphon filter

Silica gel breather is mostly used as a means of preventing moisture absorption. The conservator fitted in the transformer allows the volume of air to change due to changes in pressure and temperature. When the load on the transformer is reduced, air is drawn into the conservator from the cartridge packed with silica gel crystals.

Silica gel absorbs moisture. If silica gel is new, it is available in light pink or white colour. It absorbs the moisture in the air and turns blue. Silica gel is dried in sunlight to recondition it.

What did you learn today:-

Now you must have known what is a distribution transformer and you must have got the answer to all these questions well.

I hope you liked the information given by me. If you have any question/suggestion in your mind, you can tell me by commenting below. I will definitely answer your comment. If you liked this post, you can also share it with your friends and relatives.