Friends, today in this article we will learn about the direct current machine. I am going to give information about all these in a very good way. So let’s start.

Direct Current Machine –

The structure of direct current generator and direct current motor is the same. That is why we can use the machine as a generator.

From the point of view of structure, there is no difference between direct current motor and direct current generator. The same direct current machine can be used as both motor and generator. If the machine is connected to the power supply, then the machine will work like a motor and generate mechanical force and if the same machine is run with the mechanical force of the first conductor, then it will work like a generator and generate electrical power. Therefore, the direct current motor converts electrical energy into mechanical energy.

Although the work of both motor and generator can be done by the same machine, but the motor is of completely or partially closed structure for rough use, whereas the generator is made of open structure for cooling.

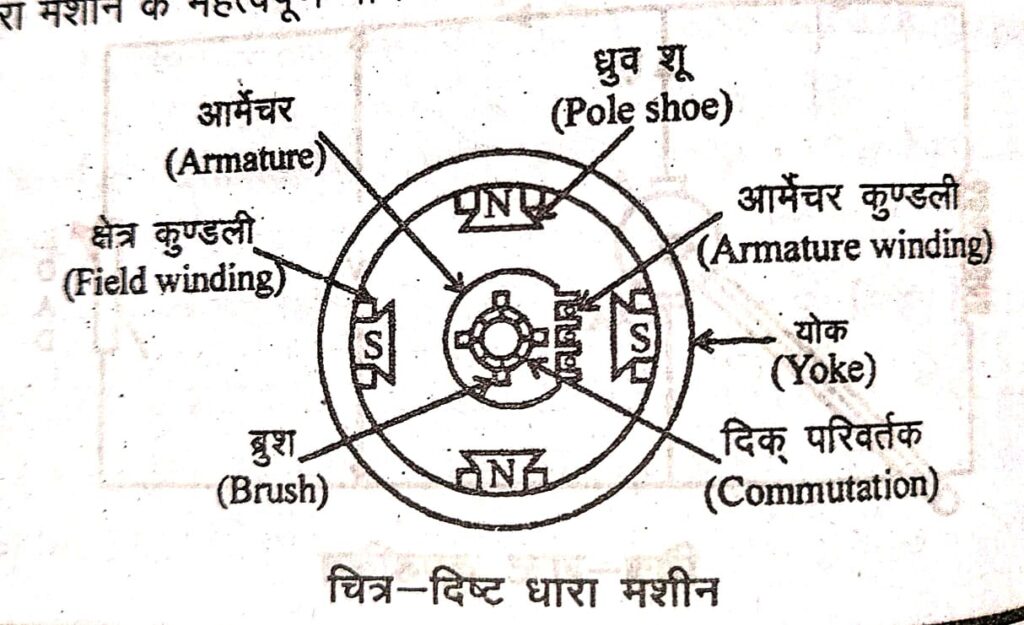

In a direct current machine, the field coils are on the stator, but in a direct current machine, there is a separate structure for two poles. The important parts of a DC machine are as follows

(1) Field magnet: pole core, pole shoe and field winding

(2) Yoke

(3) Armature core

(4) Armature winding

(5) Commutator

(6) Bearing

The parts of a DC machine are described as follows-

(1) Field magnet – A field magnet has three parts, they are as follows-

(i) Pole core

(ii) Pole shoe

(iii) Field coil

The pole core is made of iron and either soft steel laminated but for large machines both the pole core and pole shoe are made of laminated steel. The laminated pole shoe is round in shape and is near the armature. The pole core and the laminated part of the pole shoe are on the surface where the armature rotates. The pole shoe has two functions.

(a) To provide support to the magnetic coils

(b) To reduce the reluctance of the magnetic circuit and to spread the flux uniformly in the air gap due to the high transverse area of the shoe

The upper part of the field magnet which is tightened with the yoke with the help of a nut bolt. In that field magnet, the pole core and the lower part are called shoe. Inside this, a coil is made from insulated copper wires. To make the field coil, first a form of the shape of the pole core is made. Thereafter, with the help of the form, field coils are made and fixed in the pole core.

(2) Yoke – This is the outer shell of the machine, which is round in shape. Yoke is made from cast iron or cast steel and rolled steel. Yoke of small machines is made from cast iron and yoke of big machines is made from cast and rolled steel because it reduces the weight of the machine but yokes of big machines are cast in two parts and both the parts are joined with the help of nut bolt. Then it mechanizes the pole of the machine and protects it from external damage. Pole provides a path of low reluctance for the magnetic flux. Pole core is connected with the yoke due to which it has to be connected from inside.

(3) Armature core – The part of the machine which rotates is called armature. Armature is made from conductor. The armature core is made of circular plates of silicon steel of about 6.35 mm (1/4 inch) thickness of cylindrical shape. Slots are cut around its circumference to insert armature conductors or windings. Due to this, the plates are dried by coating varnish or oxide and then they are made into cylindrical shape with the help of a hydraulic press machine. By making the plates thin and applying varnish or oxide layer on them, the resistance of the eddy current path increases and as a result the eddy current loss is reduced. In large machines, an air hole is made parallel to the axis of the armature core, which helps in armature cooling. The armature core mainly installs its coils inside itself, due to which the armature core rotates in its magnetic field, then it provides a path of low resistance to the flux passing through it.

(4) Armature winding – Armature coil is made of enamelled copper wire. These coils are first wound on the firm and then they are inserted in the slots of the armature made of copper wire. Before inserting the coil in the slots of the armature, empire cloth made of copper wire and leatheroid paper is put in the slots so that the insulation of the coil is not damaged. After inserting the coil, the wood of the slots is closed with wedges and the ends of the coil are connected to the commutator.

Generally, lap coil is used for high current and low voltage and wave winding is used for low current and high voltage. Potential difference is generated by cutting the magnetic flux inside the armature coil and with its help the electric current is sent to the commutator.

(5) Commutator – See answer to question 4.

(6) Bush – Bush is made of carbon and copper in rectangular shape. These bushes are fitted in holders, which are called bush holders. These bushes are fitted on the stand like bush yoke. Bush yoke, bush holder and bush are fitted in bush gear. The work of the bush is to collect the current from the commutator and we give it to the external circuit, due to which this bush rotates the commutator on the part where the bush is fitted. Whatever is the place of the bush, we put it from one bush to another with the help of segment. Due to this, whichever coil rotates, it rotates at 90° from the line of flux. Due to this, electric sparks increase a lot and sparks from big machines can cause a lot of damage to the commutator. Hence, carbon bushes are used in big machines. The resistance of carbon is more than that of copper, due to which sparking cannot occur and at the same time, the carbon bush acts as a lubricant for the commutator.

The bush is usually fitted in a box type holder in which spring pressure is applied to maintain proper contact with the commutator and the bush is connected to the holder of the external circuit through a pigtail connection.

(7) Bearing – Either bearing balls or bearings are used to give power to the armature shaft. To run the bearing, full lubricant is applied. Bearings are usually made from gun metal and babbit metal. Ball bearings or bush bearings are used for small machines but roller bearings are used for big machines.

What did you learn today:-

Now you must have known what a direct current machine is. You must have got the answer to all these questions well.

I hope you liked the information given by me. If you have any question/suggestion in your mind, then you can tell me by commenting below. I will definitely answer your comment. If you liked this post, then you can also share it with your friends and relatives.