Friends, today in this article we will learn about transformer cooling . I am going to give information about all this in a very good way. So let’s start.

Naturally cooled transformers-

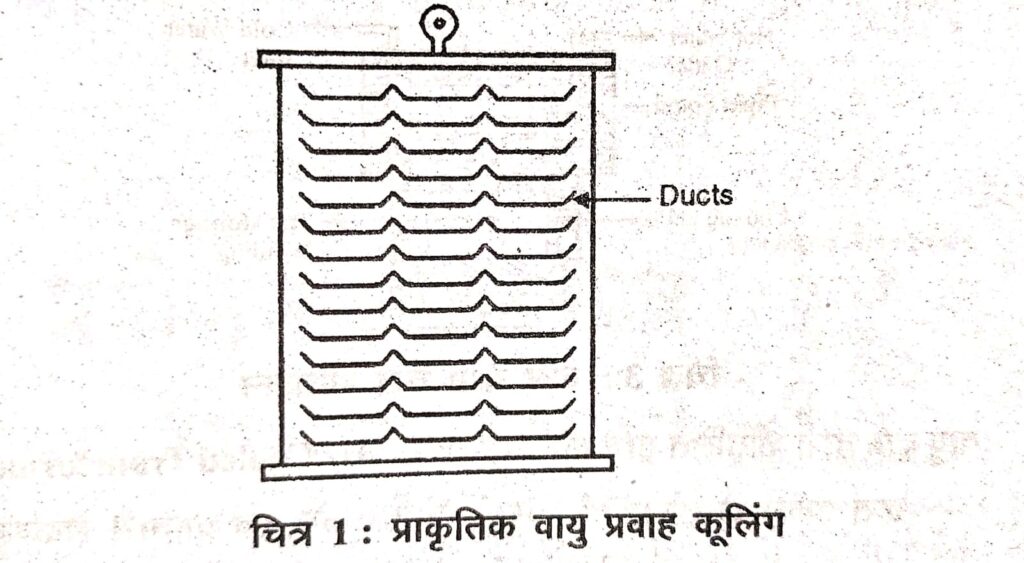

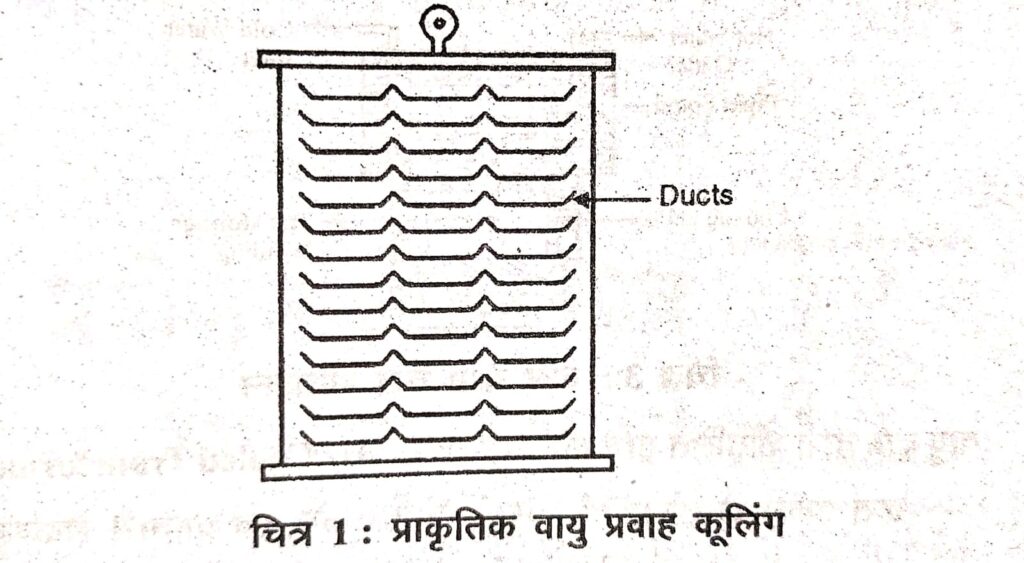

To cool a small transformer of around 20kVA, the core area is kept large so that it absorbs the heat generated. Apart from this, a duct is made on the outer part of the transformer. Natural air comes in through which it reduces the heat.

Oil cooled transformers –

Oil cooled transformers are of the following types:

(a) Natural cooling by oil –

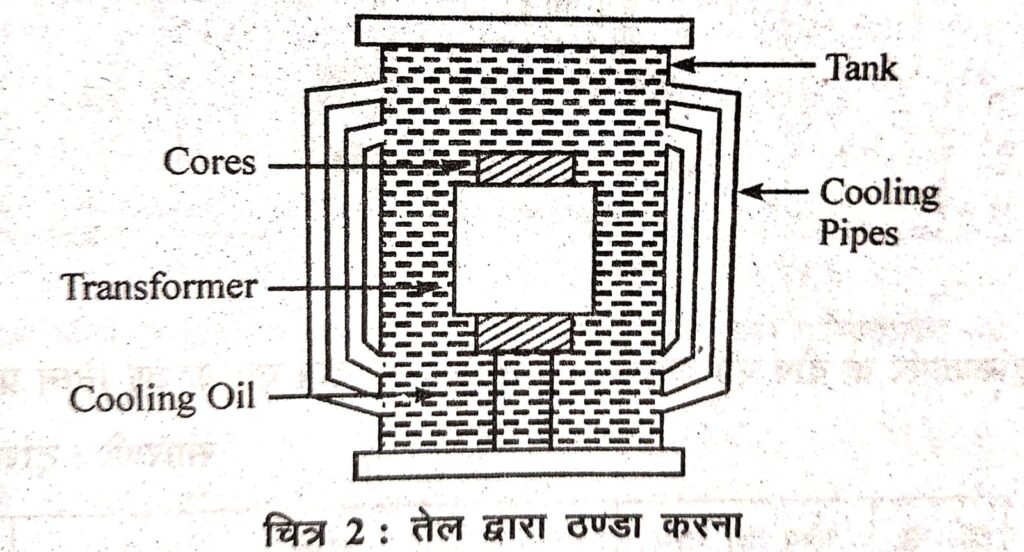

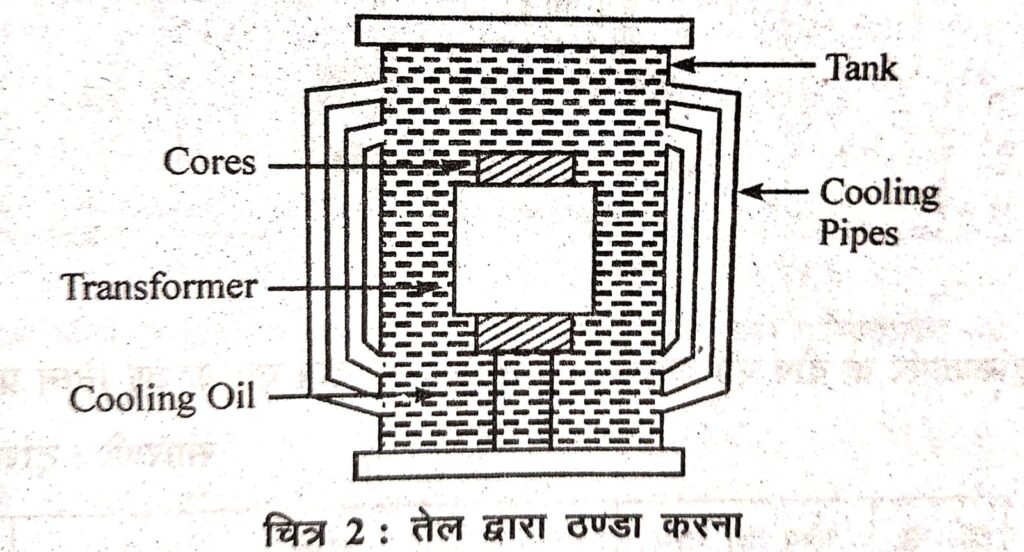

This method is adopted in transformers of higher KVA. The transformer having laminated core and winding is placed in a tank filled with oil. The oil gets heated near the winding. That hot oil moves towards the wall of the tank.

In this way the process of cooling of the oil continues. Tubes are used in large transformers as shown in the picture. The larger the area of the tubes and transformer, the faster the oil cools down and keeps the winding core cool.

(b) Oil blast cooling –

This cooling method is used in transformers having capacity of more than 500kVA. In this method, a radiator tank is also connected with the transformer tank. The oil is cooled in the radiator by the flow of air with the help of an air pump. The cooled oil is again sent from the radiator tank to the main tank. All this work is completed with the help of two pumps.

Water cooled transformer-

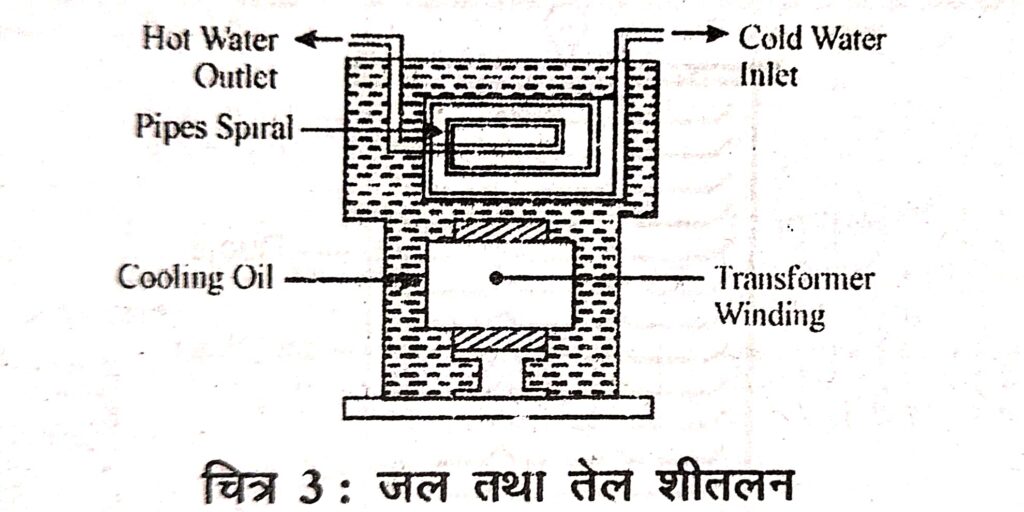

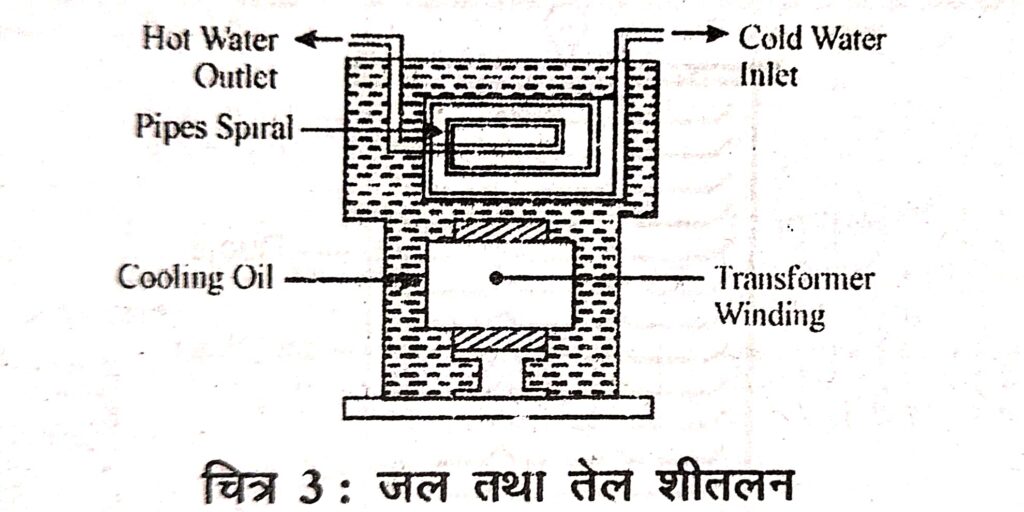

Transformers of higher capacity (KVA) are water cooled. The tank in these is large. Water pipes are wrapped around the winding (sometimes pipes are installed in the upper part as shown in the picture, the tank below is filled with oil. To cool the hot oil, the coolness of the water tube keeps it cool. Cold water is sent into the pipe from one end and the water is heated and comes out from the other end.

Air pressure cooled transformers –

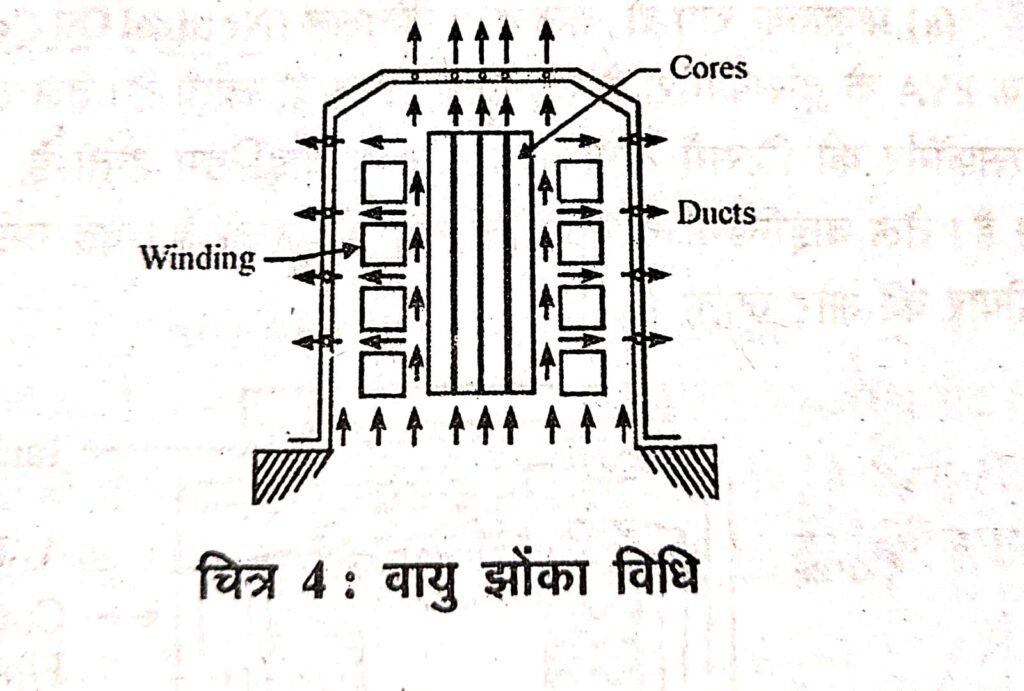

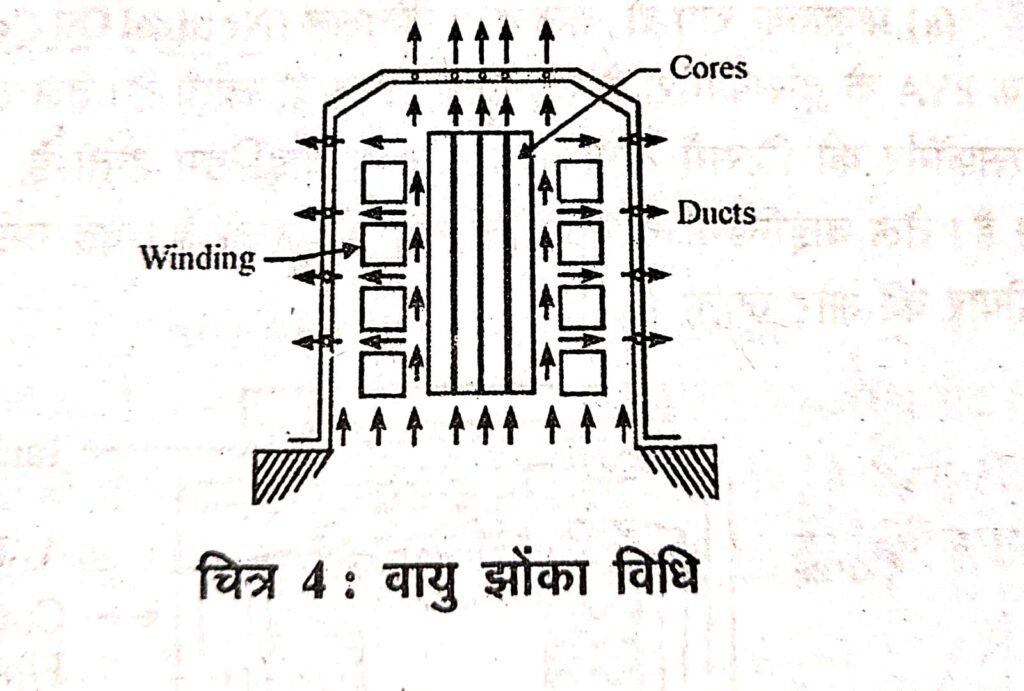

In this type of transformers, the laminated core and primary secondary winding are cooled with the help of a fan. Air ducts are made in it for the air to pass through, so that the air can circulate well all around through these routes.

What did you learn today :-

Now you must have known about transformer cooling and you must have got the answer to all these questions well.

I hope you liked the information given by me, if you have any question/suggestion in your mind, then you can tell me by commenting below, I will definitely reply to your comment. If you liked this post, then you can also share it with your friends and relatives.

Describe transformer cooling?

Friends, today in this article we will learn about transformer cooling . I am going to give information about all this in a very good way. So let’s start.

Naturally cooled transformers-

To cool a small transformer of around 20kVA, the core area is kept large so that it absorbs the heat generated. Apart from this, a duct is made on the outer part of the transformer. Natural air comes in through which it reduces the heat.

Oil cooled transformers –

Oil cooled transformers are of the following types:

(a) Natural cooling by oil –

This method is adopted in transformers of higher KVA. The transformer having laminated core and winding is placed in a tank filled with oil. The oil gets heated near the winding. That hot oil moves towards the wall of the tank.

In this way the process of cooling of the oil continues. Tubes are used in large transformers as shown in the picture. The larger the area of the tubes and transformer, the faster the oil cools down and keeps the winding core cool.

(b) Oil blast cooling –

This cooling method is used in transformers having capacity of more than 500kVA. In this method, a radiator tank is also connected with the transformer tank. The oil is cooled in the radiator by the flow of air with the help of an air pump. The cooled oil is again sent from the radiator tank to the main tank. All this work is completed with the help of two pumps.

Water cooled transformer-

Transformers of higher capacity (KVA) are water cooled. The tank in these is large. Water pipes are wrapped around the winding (sometimes pipes are installed in the upper part as shown in the picture, the tank below is filled with oil. To cool the hot oil, the coolness of the water tube keeps it cool. Cold water is sent into the pipe from one end and the water is heated and comes out from the other end.

Air pressure cooled transformers –

In this type of transformers, the laminated core and primary secondary winding are cooled with the help of a fan. Air ducts are made in it for the air to pass through, so that the air can circulate well all around through these routes.

What did you learn today :-

Now you must have known about transformer cooling and you must have got the answer to all these questions well.

I hope you liked the information given by me, if you have any question/suggestion in your mind, then you can tell me by commenting below, I will definitely reply to your comment. If you liked this post, then you can also share it with your friends and relatives.